Monday

Today we continued to build our individual boxes. I was the first one to finish my box so i started on making another one. We also started on making the top arm that holds the counter weight and weight.

Tuesday

Today we finished all of our boxes. We began to think about how we would attach the boxes to eachother appropriatly.

Wednesday

Thursday

Wednesday, June 16, 2010

WEEK 17

Monday

Today i added the truss structure to the title block and made sure it had proper dimensions and was fit to the screen. I named all my title blocks based on what part of the crane they were.

Tuesday

Was not here

Wednesday

Today we started to make our crane out of the popsicle sticks. I worked on making the base of the crane using full popsicle stick lengths. I didnt have to do any cutting.

Thursday

Today i learned how to make a proper I-beam. We made roughly 15 I-beams to get us started. We continued to cut pieces to get them the appropriate size to build the crane.

Friday

Today we started making three boxes for the bottom of the crane. We added the four corners and the trusses that connect them. We used carpenting glue to strengthen it as much as possible

Today i added the truss structure to the title block and made sure it had proper dimensions and was fit to the screen. I named all my title blocks based on what part of the crane they were.

Tuesday

Was not here

Wednesday

Today we started to make our crane out of the popsicle sticks. I worked on making the base of the crane using full popsicle stick lengths. I didnt have to do any cutting.

Thursday

Today i learned how to make a proper I-beam. We made roughly 15 I-beams to get us started. We continued to cut pieces to get them the appropriate size to build the crane.

Friday

Today we started making three boxes for the bottom of the crane. We added the four corners and the trusses that connect them. We used carpenting glue to strengthen it as much as possible

Tuesday, June 8, 2010

Tuesday, June 1, 2010

Week 16

Monday

Today i had to redo my crane design on CAD because it was not done in popsicle form. I finished the base the crane and started on my top part

Tuesday

today i finished my crane by completing the top and making it an appropriate sized and scaled according to what i would do.

Wednesday

Today i started to work on the multiple views of the base structure design. I put the three different views a new title block with dimensions showing the fine details.

Thursday

Today i completed the base structure drawing making sure it was appropriate in dimensions compared to my main drawing. I had to use the midpoint tool a lot while doing this.

Friday

Today i completed the truss structure for the part of the crane that holds the load. I made it scaled with proper dimensions and made the side and top view as well.

Today i had to redo my crane design on CAD because it was not done in popsicle form. I finished the base the crane and started on my top part

Tuesday

today i finished my crane by completing the top and making it an appropriate sized and scaled according to what i would do.

Wednesday

Today i started to work on the multiple views of the base structure design. I put the three different views a new title block with dimensions showing the fine details.

Thursday

Today i completed the base structure drawing making sure it was appropriate in dimensions compared to my main drawing. I had to use the midpoint tool a lot while doing this.

Friday

Today i completed the truss structure for the part of the crane that holds the load. I made it scaled with proper dimensions and made the side and top view as well.

Monday, May 31, 2010

Group Problem Solving

Principles - Dont jump to solutions before defining the problem. Solve problems close to the source. attend to the interests of all stakeholders.

Skills - Brainstorming, Facilitation

Guidlines

Identify a recorder and facilitator (can be the same person)

Clarify the issue or question

If appropriate, first generate ideas individually on paper

Begin recording ideas from the group --sequentially or otherwise

Encourage “piggy-backing” and “wild or crazy” ideas

Discourage criticism or judgmental comments

Push past “the pause”

Cluster before you prioritize

A P rocess I provement Mo elA A P rocess I provement Mo elA A P rocess I provement Mo elA

(The aim of the process --How ar et ing s u pps dt oh p pe?

Rea i y

(H wdo t hingsa tual yha pe ?

Root au es

( W hatw ould acc unt for an y gaps be w e enthe a ma drea ity )

Impro e me t pti ns

( W ha a reo t ons th a tmig t he l pcl set e gap?)

V lu -ad ed I ple e nta io

(Of th e m ny options whic o es w llad value H ww o ldt ey be imple mente ? )

Ev luati n nd C nti uo s m roveme t

(Wha a ret ecri eri for s c es Wha i the Rea i yRoot au esImpro e me t pti nsV lu -ad ed I ple e nta ioEv luati n nd C nti uo s m roveme tRea i yRoot au esImpro e me t pti nsV lu -ad ed I ple e nta ioEv luati n nd C nti uo s m roveme t

Skills - Brainstorming, Facilitation

Guidlines

Identify a recorder and facilitator (can be the same person)

Clarify the issue or question

If appropriate, first generate ideas individually on paper

Begin recording ideas from the group --sequentially or otherwise

Encourage “piggy-backing” and “wild or crazy” ideas

Discourage criticism or judgmental comments

Push past “the pause”

Cluster before you prioritize

A P rocess I provement Mo elA A P rocess I provement Mo elA A P rocess I provement Mo elA

(The aim of the process --How ar et ing s u pps dt oh p pe?

Rea i y

(H wdo t hingsa tual yha pe ?

Root au es

( W hatw ould acc unt for an y gaps be w e enthe a ma drea ity )

Impro e me t pti ns

( W ha a reo t ons th a tmig t he l pcl set e gap?)

V lu -ad ed I ple e nta io

(Of th e m ny options whic o es w llad value H ww o ldt ey be imple mente ? )

Ev luati n nd C nti uo s m roveme t

(Wha a ret ecri eri for s c es Wha i the Rea i yRoot au esImpro e me t pti nsV lu -ad ed I ple e nta ioEv luati n nd C nti uo s m roveme tRea i yRoot au esImpro e me t pti nsV lu -ad ed I ple e nta ioEv luati n nd C nti uo s m roveme t

Thursday, May 27, 2010

Week 15

Tuesday

Today i continued to work on my crane on AutoCad. I made the prop that holds the weight and counter weight on the crane.

Wednesday

Was not here today

Thursday

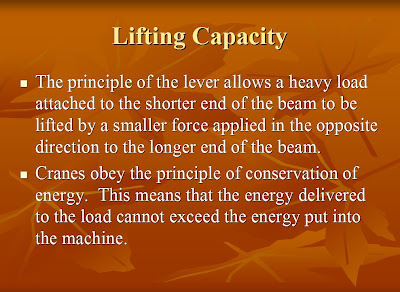

Today we made a presention on powerpoint about cranes. We discussed how to properly design a crane and how the trusses are supposed to work to incrase the stability of your crane.

Friday

Today i worked on my Cad drawing. I made the popsicle sticks scaled to fit on my drawing so that i could be as accurate as possible

Today i continued to work on my crane on AutoCad. I made the prop that holds the weight and counter weight on the crane.

Wednesday

Was not here today

Thursday

Today we made a presention on powerpoint about cranes. We discussed how to properly design a crane and how the trusses are supposed to work to incrase the stability of your crane.

Friday

Today i worked on my Cad drawing. I made the popsicle sticks scaled to fit on my drawing so that i could be as accurate as possible

Thursday, May 20, 2010

Crane Design Ideas and Initial thoughts

The engineering design process

The Engineering Design Process

- Creative process

- Problem solving – the big picture

- No single "correct" solution

- Technical aspects only small part

Elements of Design the Process

ØProblem Identification

ØResearch Phase

ØRequirements Specification

ØConcept Generation

ØDesign Phase

ØPrototyping Phase

ØSystem Integration

ØMaintenance Phase

Needs Identification

1.Collect information

2.Interpret information

3.Organize needs hierarchy

4.Determine relative importance of needs

5.Review outcomes and process

Requirements Specification

ØIdentifies requirements design must satisfy for success

1. Marketing requirements

§Customer needs

2. Engineering requirements

§Applies to technical aspects

§Performance requirements

Properties of Engineering Requirements

1.Abstract – what, not how

2.Unambiguous – unique and specific

ØUnlike marketing requirements

3.Traceable – satisfy need?

4.Verifiable – test/measure

Example Engineering Requirements

vPerformance and Functionality

1.Will identify skin lesions with a 90% accuracy

2.Should be able to measure within 1mm

vReliability

1.Operational 99.9% of the time

2.MTBF of 10 years

vEnergy

1.Average power consumption of 2 watts

2.Peak current draw of 1

Concept Generation and Evaluation

ØExplore many solutions

§Brainstorm

ØSelect the best solution

§Based on needs and constraints

ØCreativity

§ Development of new ideas

ØInnovation

§ Bringing creative ideas to reality

Concept Generation

ØSubstitute

ØCombine

ØAdapt

ØModify

ØPut to other use

ØEliminate

ØRearrange or reverse

Barriers to Creativity

ØPerceptual blocks

ØLimiting problem space

ØEmotional blocks

•Fear of failure – “fail early and often”

ØEnvironmental blocks

• Engineering cultural bias

ØIntellectual and expressive blocks

• Understand tools

Design Considerations

1)WORST CASE DESIGN

ØComponent variation

ØEnvironmental conditions

ØUse computer simulations

2) RELIABILITY

Ømeasured by MTBF, failure rate = 1/MTBF

Ømechanical parts fail first

Ødesign redundancy into system

Øsimple system/fewer parts = more reliable

3) SAFETY

Øidentify failure modes

Øprovide protection

4) TEST

Ødesign for ease of test

5) PRODUCTION/MANUFACTURING

Øconsider ease of assembly

Design Methodologies: Top-Down

ØAlso called “functional decompostion“

Øimplementation details considered only at the lowest level

Øtop‑down design, is not so clean and linear in practice

ØOften implementation‑level commitments are made at high levels in the design process

Design Methodologies

CASE‑BASED:

ØResearch a specific, similar design case study

ØModel your process on that

INCREMENTAL REDESIGN:

ØFind an existing design and "unravel" the design from the bottom up

ØModify as required

ØDetailed and least global aspects of the design are explored and redesigned, if necessary, first

ITERATIVE REFINEMENT:

ØAn iterative top‑down approach

ØFirst a rough, approximate and general design is completed

ØThen we do it finer, more exact and more specific

ØThis process continues iteratively until the complete detail design in done

BOTTOM‑UP DESIGN:

ØOpposite of top‑down

ØStart at the bottom with detail design

ØTo do this, you must have some idea of where you are going. So, often this becomes...

HYBRID DESIGN:

ØCombines aspects of both top‑down and bottom‑up

ØMore practical design approach then pure top‑down

ØStart with a top‑down approach, but have feedback from the bottom

"EXPLORER" METHOD:

ØTypically used for new design ideas or research. It is useful in initial design and specification stages, and is often used when in "unfamiliar territory":

1)Move in some direction; e.g. toward the library, telephone, domain expert's office, etc.

2)Look at what you find there.

3)Record what you find in your notebook.

4)Analyze findings in terms of where you want to be.

5)Use results of analysis to choose next direction.

6)Back to 1) and continue exploring

Design Group (Team)

ØEngineering projects require diverse skills

ØThis creates a need for group (team) work

ØSelect members based on skills

1.Technical

2.Problem-solving

3.Interpersonal

ØDevelop decision making guidelines

1.Decision by authority (leader)

2.Expert Member

3.Average member opinion

4.Majority

5.Consensus

ØTeams that spend time together tend to be successful teams

ØRespect each other

1.Listen actively

2.Consider your response to others

3.Constructively criticize ideas, not people

4.Respect those not present

5.Communicate your ideas effectively

6.Manage conflict constructively

ØHold effective meetings

1.Have an agenda

2.Show up prepared

3.Pay attention

4.Schedule time and place of next meeting

5.Summarize

ØAssign tasks and responsibilities

Project Management

ØWork breakdown structure

üHierarchical breakdown of tasks and deliverables need to complete project

ØActivity

1.Task – action to accomplish job

2.Deliverable – e.g. circuit or report

ØDefine for each activity

1.Work to be done

2.Timeframe

3.Resources needed

4.Responsible person(s)

5.Previous dependent activities

6.Checkpoints/deliverables for monitoring progress

Tuesday, May 18, 2010

Sectional Drawing Test Review

Part Drawing - Detail drawings completely describe a single part with multiview orthographic projection. Provides enough information to economically manufacture a part.

Assembly Drawing - Assembly drawing are used to show the position and functional relationship of parts in an assembly. Do not have dimensions on them.

Section Views - Sections views are used to clarify internal detail and to avoid dimensioning to hidden lines. They are established by referencing a cutting plane. They depict the exact location on the part from which the section view will be projected.

Cross Hatching - The general purpose cross hatch is used in most individual detail component drawings and in assembly applications where no confusion will result. Each of the assembled components are depicted with a different crosshatch angle. Specific cross hatch symbols can be used to represent different material types.

Half Sections - Half section views are the result of cutting planes beign psotion on parts that only half of the resulting view or projection is shown in the section. They are used on objects of symmetry.

Project Management

ØDefine for each activity

1.Work to be done

2.Timeframe

3.Resources needed

4.Responsible person(s)

5.Previous dependent activities

6.Checkpoints/deliverables for monitoring progress

Assembly Drawing - Assembly drawing are used to show the position and functional relationship of parts in an assembly. Do not have dimensions on them.

Section Views - Sections views are used to clarify internal detail and to avoid dimensioning to hidden lines. They are established by referencing a cutting plane. They depict the exact location on the part from which the section view will be projected.

Cross Hatching - The general purpose cross hatch is used in most individual detail component drawings and in assembly applications where no confusion will result. Each of the assembled components are depicted with a different crosshatch angle. Specific cross hatch symbols can be used to represent different material types.

Half Sections - Half section views are the result of cutting planes beign psotion on parts that only half of the resulting view or projection is shown in the section. They are used on objects of symmetry.

Project Management

ØDefine for each activity

1.Work to be done

2.Timeframe

3.Resources needed

4.Responsible person(s)

5.Previous dependent activities

6.Checkpoints/deliverables for monitoring progress

Week 14

Monday

Today we opened our blogs for mr.d to mark and check our progress so far this year. We then watched a movie about the world trade centre. This movie was very educational and interesting, the movie explained how the world trade centre was built and explained the theory on how the building most likely collapsed during 9/11

Tuesday

Today we updated our blogs and wrote a note. We then were told about the cranes we would be building within the next couple of weeks

Wednesday

I was not here today

Thursday

Today i started to design my crane on AutoCad. I started the base of the crane. I made the trusses the length of a popsicle stick and the base about 3/4 of a popsicle stick

Friday

Today i started to design the top part of my crane that carries the load and holds the counter weight. I made the one end longer than the other to hold the load and the other to hold the counter weight.

Today we opened our blogs for mr.d to mark and check our progress so far this year. We then watched a movie about the world trade centre. This movie was very educational and interesting, the movie explained how the world trade centre was built and explained the theory on how the building most likely collapsed during 9/11

Tuesday

Today we updated our blogs and wrote a note. We then were told about the cranes we would be building within the next couple of weeks

Wednesday

I was not here today

Thursday

Today i started to design my crane on AutoCad. I started the base of the crane. I made the trusses the length of a popsicle stick and the base about 3/4 of a popsicle stick

Friday

Today i started to design the top part of my crane that carries the load and holds the counter weight. I made the one end longer than the other to hold the load and the other to hold the counter weight.

Friday, May 14, 2010

Tuesday, May 11, 2010

week 13

Monday

WAs sick

Tuesday

Today i did the orthographic and isometric drawings worksheet. hello mr d. I handed it in then worked on the next assignement in autoCad.

Wednesday

Today i continued to work on my control bracket drawing in AutoCad. I began to draw each side and learned a few new tools such as the quad tool and fillet tool. Each of these tools i had to use when rounding my corners and drawing the proper hidden lines. Today i managed to finish everything except for the hidden lines and dimensions

Thursday

Today i added the hidden lines to my drawing. I found that this drawing was a little harder than most of the other drawings that we have done earlier in AutoCad.

Friday

Today i added the dimensions to my front view, top and view and side view. I also put it on the title block and added it to my blog. I learned how to resize my drawing to fit the screen on the title block

WAs sick

Tuesday

Today i did the orthographic and isometric drawings worksheet. hello mr d. I handed it in then worked on the next assignement in autoCad.

Wednesday

Today i continued to work on my control bracket drawing in AutoCad. I began to draw each side and learned a few new tools such as the quad tool and fillet tool. Each of these tools i had to use when rounding my corners and drawing the proper hidden lines. Today i managed to finish everything except for the hidden lines and dimensions

Thursday

Today i added the hidden lines to my drawing. I found that this drawing was a little harder than most of the other drawings that we have done earlier in AutoCad.

Friday

Today i added the dimensions to my front view, top and view and side view. I also put it on the title block and added it to my blog. I learned how to resize my drawing to fit the screen on the title block

Thursday, May 6, 2010

Week 12

Monday

Today we were given a drawing that we were told to sketch using our knowledge of orthographic drawing. I made a sketch of my drawing on paper based on the appropriate lenght height and width sizes.

Tuesday

Today i put my sketch of the vertical brace onto AutoCAD. I found this drawing a little more complicated then some of the others but i managed to figure my way through a few of the different angles and length sizes.

Wednesday

Today i continued to work on my vertical brace. I finished off the drawing then added dimensions and the angle degrees.

Thursday

Today i put the vertical brace onto the title block. I added the title of it, my name and my school. I also made the size of my drawing properly fit the page in the model space.

Friday

Today mr.D checked my drawing that i did on AutoCad. I made corrections to the ones that needed work.

Today we were given a drawing that we were told to sketch using our knowledge of orthographic drawing. I made a sketch of my drawing on paper based on the appropriate lenght height and width sizes.

Tuesday

Today i put my sketch of the vertical brace onto AutoCAD. I found this drawing a little more complicated then some of the others but i managed to figure my way through a few of the different angles and length sizes.

Wednesday

Today i continued to work on my vertical brace. I finished off the drawing then added dimensions and the angle degrees.

Thursday

Today i put the vertical brace onto the title block. I added the title of it, my name and my school. I also made the size of my drawing properly fit the page in the model space.

Friday

Today mr.D checked my drawing that i did on AutoCad. I made corrections to the ones that needed work.

Friday, April 30, 2010

Week 11

Monday

Was not here

Tuesday

Today i did the dimensions and centre lines of the adaptor. I learned how to properly set centre lines and use the apporpiate line types such as hidden lines, continuous lines, and dashed lines. I also posted my drawings on my blog.

Wednesday

Today i worked continued to use autoCAD on my next drawing. I started the new drawing of CAD problem 1.4. It was a little harder than the others but i managed to figure it all out. Less lines were given specific distances and i was forced to use a lot of other liens ot figure the smaller ones out.

Thursday

Today i finished all the different views of CAD problem 1.4. I learned how to make better use of angles and distances effectively when drawing my shapes. I also started to do the dimensions of the drawing.

Friday

Today i finished the dimensions and centre lines and posted it on my blog. I learned how to scale down my drawings when posted on the model paper. I learned how to professionaly post the name of the drawing, my name, and the name of my school.

Was not here

Tuesday

Today i did the dimensions and centre lines of the adaptor. I learned how to properly set centre lines and use the apporpiate line types such as hidden lines, continuous lines, and dashed lines. I also posted my drawings on my blog.

Wednesday

Today i worked continued to use autoCAD on my next drawing. I started the new drawing of CAD problem 1.4. It was a little harder than the others but i managed to figure it all out. Less lines were given specific distances and i was forced to use a lot of other liens ot figure the smaller ones out.

Thursday

Today i finished all the different views of CAD problem 1.4. I learned how to make better use of angles and distances effectively when drawing my shapes. I also started to do the dimensions of the drawing.

Friday

Today i finished the dimensions and centre lines and posted it on my blog. I learned how to scale down my drawings when posted on the model paper. I learned how to professionaly post the name of the drawing, my name, and the name of my school.

Wednesday, April 28, 2010

Tuesday, April 27, 2010

MECHANICAL DRAWING

Dimensions:

are the text that is provided with a drawing that describe the exact size and location for the features shown. also known as size descriptions.

Conversions:

1 in. = 2.54 cm

2 methods of dimensios

aligned and unit directional

do not place dimensions on object

do not place dimensions on hidden lines.

leaders should not be vertical or horizontal only at 30-60*

are the text that is provided with a drawing that describe the exact size and location for the features shown. also known as size descriptions.

Conversions:

1 in. = 2.54 cm

2 methods of dimensios

aligned and unit directional

do not place dimensions on object

do not place dimensions on hidden lines.

leaders should not be vertical or horizontal only at 30-60*

Thursday, April 22, 2010

Subscribe to:

Comments (Atom)